Liugong LG50C Excavator Bucket Teeth

Place of Origin: China

Material: 30CrMnSi

Process: Forging

Part No.: 72A0005

Hardness: 50-53HRC tip part

Tensile: 1450MPA

Impact: ≥20J/c㎡

Compatible Brand: Liugong

Description

Our bucket teeth are forged, not casting.

They are used for a wide range of excavators, such as Hitachi,

Komatsu, Daewoo, Caterpillar, Volvo, Kobelco, Hyundai, Liugong etc.

Parameters

| Place of Origin | China |

| Material | 30CrMnSi |

| Process | Forging |

| Part No. | 72A0005 |

| Hardness | 50-53HRC tip part |

| Tensile | 1450MPA |

| Impact | ≥20J/c㎡ |

| Weight | 5.3kg |

| Compatible Brand | Liugong |

| Fit Machine | Liugong 50C |

Product Advantage

- Technology

- Forging is a kind of pressure on the metal material by forging machinery, to obtain a certain mechanical property, shape and size of forging plastic deformation.

- Performance

- Our forging bucket teeth are widely applied in rock digging, ice-breaking and mine-digging, earth-moving and other severe working environments, highly increase the working efficiency, and decrease the replacement and maintenance cost.

- Material

- 30CrMnSi, which includes several alloy elements, having great rigidity, tenacity, thus to guarantee the metal wear-resistance, after forging process, the metal mechanical properties are much better than casting, thus forging bucket teeth are more wear-resistant and longer durable.

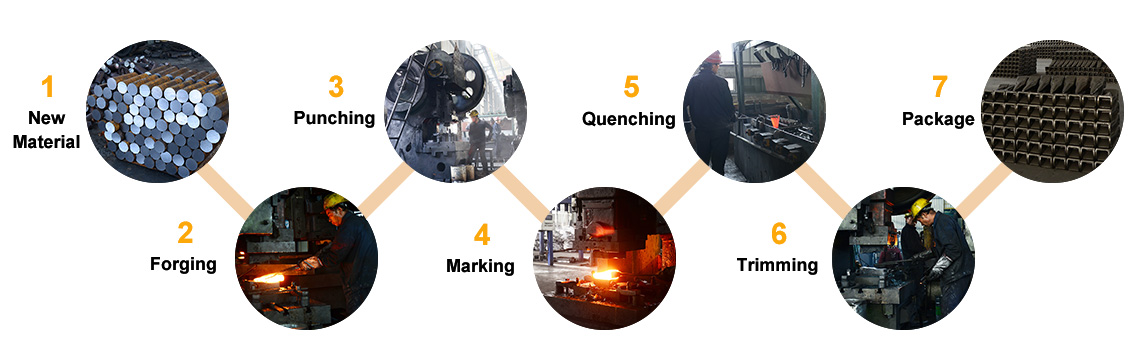

Forged Bucket Teeth Production Process

Inquiry